Ongoing partnership keeps UK water treatment projects on track and on time.

Some client relationships start with a formal tender process; others begin with a well-timed conversation. In this case, a happy accident led to the start of a long-term collaboration between Kingfisher Profiles, Bending & Fabrication and a UK-based manufacturer of water treatment equipment.

The Client (anonymised for confidentiality)

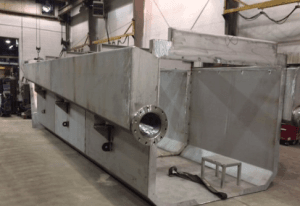

An established UK and global manufacturer of stainless steel equipment for the municipal and industrial water and wastewater treatment sector. Their products are used in treatment plants across the country and must meet stringent performance, hygiene, and durability requirements. The company is reputed for their engineering and manufacturing services, along with strict compliance with industry standards.

The Challenge

The client needed a reliable metalwork partner capable of consistently delivering stainless steel components to exact specifications.

Parts such as launders and chutes have to be produced with precision, attention to hygiene, corrosion resistance, and within tight lead times. Fabrication quality directly impacts downstream project timelines, meaning any delays or rework can quickly escalate and disrupt internal production schedules.

The Solution

The relationship began when we approached the client, recognising a strong synergy between our fabrication capabilities and the client’s manufacturing requirements. Being local helped initiate the conversation, but it was the quality of our facility and team that turned an initial meeting into a robust working partnership.

Speaking about the origins of the relationship, the client recalls: “We initially chose to work with Kingfisher by happy accident, as they are local to our business… They recognised that they offered specialist fabrication services that had synergy with our business. They invited us to see their facility and after some communication, it was clear that Kingfisher had the facilities, capability in specialist fabrication, and technical expertise, especially with stainless steel.”

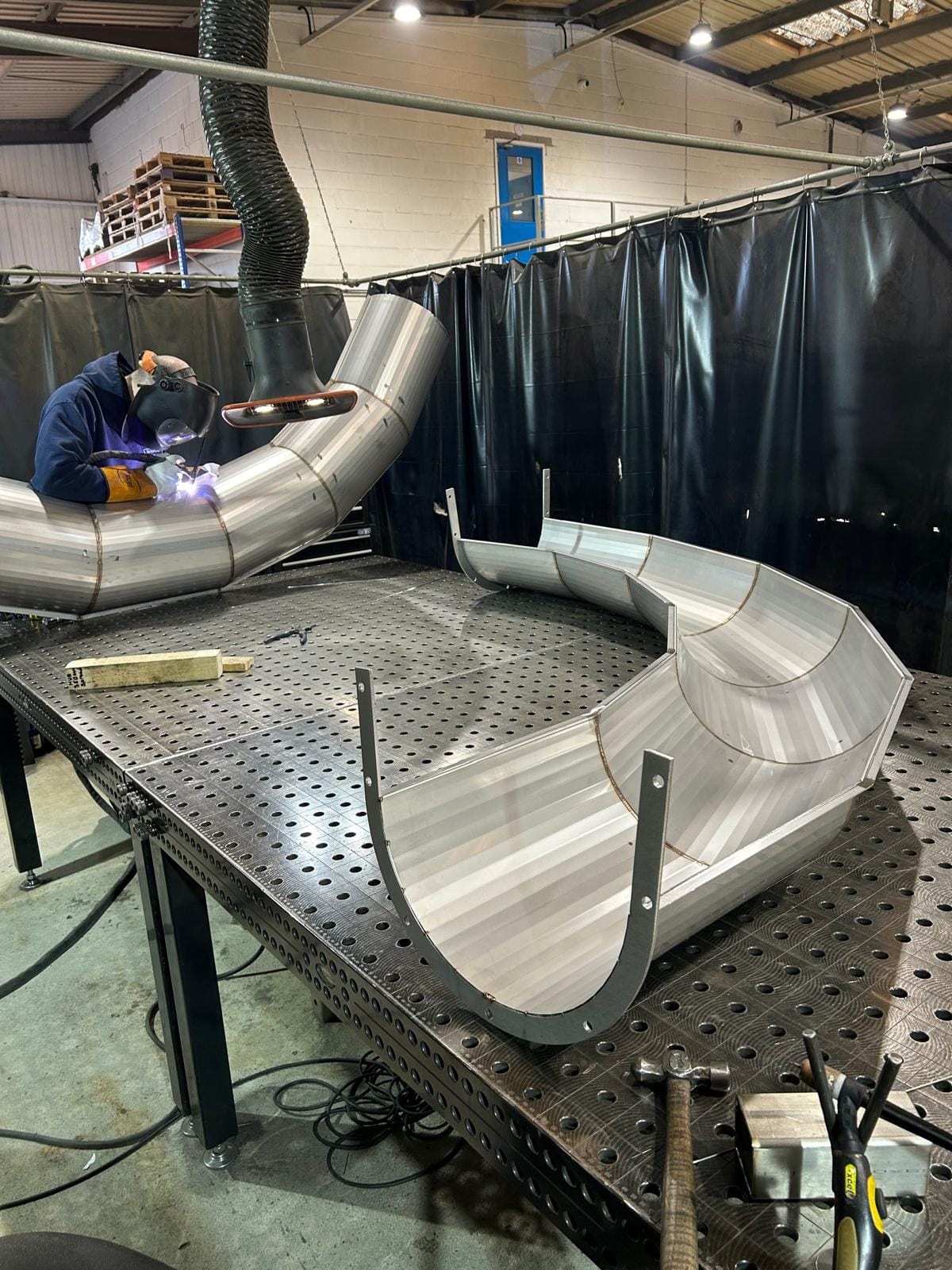

Since then, Kingfisher has supported the client with a range of fabricated components for water treatment applications, including stainless steel launders, chutes, and associated parts. Each item is laser cut, folded, fabricated, and passivated in house, ensuring full control over quality, finish, and turnaround.

The Results

Over time, the client has come to rely on us as a trusted and responsive partner: “We know we can rely on Kingfisher to deliver what we need, when we need it, without compromising standards”.

The client found Kingfisher to be particularly excellent when it comes to:

- Improved turnaround times

- Reduced internal bottlenecks

- Great consistency across fabrication batches

- Smooth project delivery

- Confidence in meeting sector-specific standards

When asked about our industry knowledge, the client said: “Kingfisher understands the standards and specifications that come with the water treatment industry… Their ability to meet exacting fabrication requirements helps us maintain quality and consistency across our projects. That kind of reliability is critical in the water treatment sector.”

Ongoing Relationship

This has been a collaborative partnership since 2022 The client praises our working style, particularly our communication and proactiveness: “Communication from Kingfisher is always clear and timely, and they are proactive in identifying potential issues before they become problems. [… ] Their attention to detail and ability to solve technical challenges quickly really stands out.”

As part of this ongoing partnership and similar work for other clients in the sector, Kingfisher produces a wide range of stainless steel and specialist components, including:

- Launders

- Chutes

- Hoppers

- Auger covers

- Support stands

- Bypass tanks (various sizes, site-specific)

- ISW nozzles

- U flange gaskets

- Various channel brackets and angle brackets (site-specific)

- Bar screens

- Hand raked bar screens

All items are manufactured to client specifications, with full in-house capability from laser cutting and folding to fabrication and passivation, ensuring quality, consistency, and compliance.

What’s Next?

With increasing pressure on the water treatment sector to deliver reliable and compliant infrastructure, the need for trusted metalwork partners has never been greater.

For this client, Kingfisher continues to play a vital role in supporting the delivery of stainless steel equipment: meeting demanding timelines, reducing internal resourcing pressure, and maintaining consistency across complex fabrication requirements.

Reflecting on the working relationship, the client noted: “That smooth delivery and reliability have a positive knock-on effect across the entire project lifecycle”.

As more companies in this sector face similar fabrication challenges, Kingfisher is well-positioned to support. With capabilities spanning laser cutting, CNC folding, fabrication, and surface treatment, combined with deep experience in stainless steel work for water treatment applications, we offer a trusted one-stop fabrication partner for manufacturers in the water treatment sector.

This case study is just one example of what Kingfisher PBF does best, supporting the UK’s water treatment sector with reliable metalwork.

Contact Us

If, like us, you are attending the Water, Wastewater & Environmental Management Expo on 17-18 September and are exploring new supplier relationships, we would be happy to show you the kind of work we deliver. Get in touch:

🌐 Website

📞 01249 448860

✉️ enquiries@kingfisher-pbf.com

Back to News